Introduction

When it comes to ensuring that your water is free of hardness, a water softener system is essential, and at the heart of this system is the resin. Water softener resin is a vital component that helps reduce mineral content, primarily calcium and magnesium, which cause water hardness. National Minerals provides high-quality resins that ensure efficient softening for both residential and industrial applications.

1. What Is Water Softener Resin?

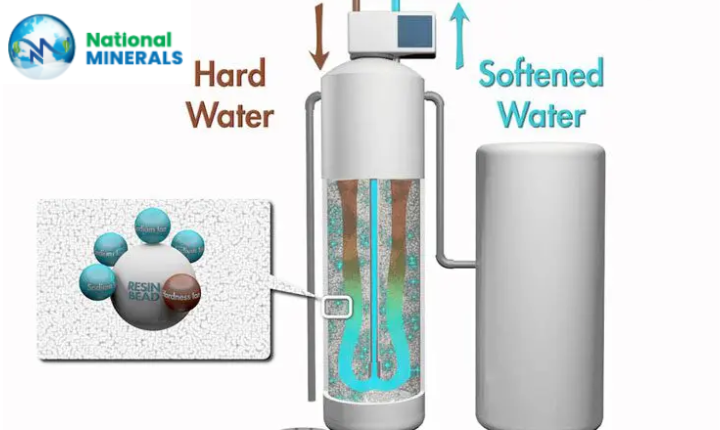

- Water softener resin is a synthetic polymer that facilitates ion exchange, the process used to soften hard water. These resins are usually tiny, bead-like materials made of durable polystyrene and divinylbenzene. They are designed to trap the minerals responsible for water hardness.

- National Minerals' High-Quality Resin: When choosing water softener resin, the quality is paramount. National Minerals specialises in producing durable and long-lasting resins that deliver consistent results in softening water.

2. How Does Water Softener Resin Work?

The ion exchange process is crucial to understanding how resin beads operate. As hard water flows over the resin, calcium and magnesium ions are attracted and bound to the resin, while sodium or potassium ions are released, softening the water. Over time, the resin beads become saturated and need to be regenerated.

The Role of National Minerals: By offering premium ion-exchange resins, National Minerals

ensures optimal performance in water treatment systems, making the softening process seamless and efficient.

3. Types of Water Softener Resins

There are two main types of resins used in water softening:- Cation Resin (Standard): Used for general water softening, cation resin beads exchange calcium and magnesium ions with sodium or potassium ions.

- Fine Mesh Resin:This type of resin is smaller and denser, making it suitable for removing iron along with hardness.

Why Choose National Minerals?

National Minerals provides both standard and fine mesh resin options to meet various water softening needs, ensuring effective treatment even in areas with high iron content.

4. Factors to Consider When Choosing Water Softener Resin

Selecting the right resin is crucial for the effectiveness and longevity of your water softening system. Key factors to consider include:

- Water Hardness Level: Determine the mineral content in your water to choose the most suitable resin type.

- Iron Content: If your water supply has a high iron concentration, opting for fine mesh resin might be necessary.

- Resin Longevity: High-quality resins, like those from National Minerals, are more durable and offer a longer service life.

National Minerals Expertise: With extensive knowledge in water treatment solutions, National Minerals provides resins that address varying levels of water hardness and contamination.

6. How to Maintain Water Softener Resin

Proper maintenance of your water softener system and its resin bed can prolong the efficiency of your water softening unit.

- Regular Regeneration: The resin needs to be periodically regenerated with a brine solution to recharge its ion-exchange capacity.

- Resin Replacement: Over time, resin beads can lose effectiveness. High-quality resins, like those from National Minerals, typically last 10-15 years before needing replacement.

- Cleaning the Resin Bed: Using specialized cleaners can help remove contaminants and prolong the life of the resin.

Tips from National Minerals: National Minerals recommends routine checks and using compatible cleaning agents to maintain the resin's performance.

7. Environmental Considerations

While water softeners are beneficial, there are some environmental concerns, particularly regarding the discharge of salt and the impact on wastewater systems.

Innovations in resin technology, like those offered by National Minerals

, are helping to mitigate these issues.

Sustainability Initiatives: National Minerals is committed to developing eco-friendly resin solutions that minimise environmental impact while maintaining high efficiency in water treatment.

8. Frequently Asked Questions about Water Softener Resin

- How often should resin be replaced? Typically, every 10-15 years, but it depends on water quality and usage.

- Can resin beads be recycled? Yes, some resins can be regenerated and reused, though it’s essential to consult experts like National Minerals for the best practices.

- What affects the lifespan of water softener resin? Factors include water hardness, iron content, and regular maintenance practices.

Expert Guidance from National Minerals: For any questions or concerns, National Minerals provides expert support and resources to help you get the most out of your water softening system.

9. Innovations in Resin Technology

The field of water treatment is constantly evolving, and advancements in resin technology are improving efficiency and sustainability.

National Minerals' Commitment to Innovation:By investing in research and development, National Minerals is at the forefront of creating next-generation resins that are more effective and environmentally friendly.

Conclusion: Why Invest in Quality Water Softener Resin?

Investing in high-quality water softener resin

, such as the options provided by National Minerals, can transform your water treatment experience. With improved water quality, extended appliance life, and reduced maintenance needs, it’s a worthwhile investment for both residential and industrial applications.

Partner with National Minerals:For reliable and high-performance resin solutions, National Minerals is your go-to source, offering products that meet the highest standards of quality and efficiency.